AKRO-PLASTICS is a leader in the rotational molded plastics industry because of our commitment to providing high quality products and services. Our dedication to customer satisfaction is our first priority. We can assist you with every phase of your project, from concept & design, to distribution of the final product. Our fully equipped, dedicated facility provides custom molding for all volume requirements.

When cost is a factor, rotational molding has the advantage over other types of processes. In comparison to injection and blow molding, rotational molding can easily produce large and small parts in a cost effective manner. Tooling is less expensive because there's no internal core to manufacture. Since there is no internal core, minor changes can be easily made to an existing mold. Because parts are formed with heat and rotation, rather than pressure, molds don't need to be engineered to withstand the high pressure of injection molding. Production costs for product conversions are reduced because lightweight plastics replace heavier, often more costly materials. Which makes rotational molding as cost effective for one-of-a-kind prototypes as it is for large production runs.

Utilizing SolidWorks 3D & Fusion 360 we can create detailed schematics for product prototypes and tooling.

5 Rotational Molding Machines allows Akro-Plastics the ability to mass produce many different products in almost any size.

Upon completion of our clients products, Akro-Plastics will package & ship directly to our clients for more efficient distribution.

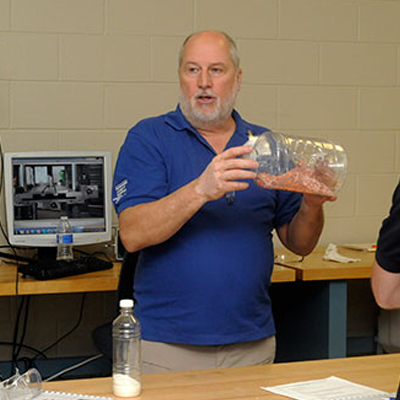

Welcome to the About Us section where you can get an introduction to the experienced driving forces behind Akro-Plastics. You can hover over the pictures for background in our business.

Jerry Ramsey, is the owner and President started Akro-Plastics after purchasing our building in 1987 and installing one machine. Jerry, whose degree is in Engineering, has an extensive knowledge of the plastics industry and is involved day-to-day operation of the company. Jerry also is a Roto-Molding instructor for classes at Penn College in Pennsylvania and has an extensive knowledge of the plastics industry.

Justin Cart is the Plant Production Manager who has extensive experience in Roto-molding as a machine Operator and Supervisor for multiple companies before becoming our Plant Production Manager in 2019.

Larry Thouvenin works with our customers on pricing and contracts. Larry has 19 years in the Roto-molding industry, including 16 years in quality and has had Plant Management experience. Larry understands the level of quality our customer’s desire and what is needed to build a solid relationship with our customers.

Fred Maurer is the Director of Human Resources and has a degree in Business and worked previously for IBM for 36 years in Management, Human Resources,Finance and Administration before joining Akro-Plastics in 2007. He leads our efforts in Human Resources, staffing, benefits and coordinating efforts between our staff and employees.

Jen Allen is our Office Manager and is involved with the Financial Operation of our company. Jen has been working for Akro-Plastics for over 20 years.

Akro-Plastics today is a custom Rotational molder located in Kent, Ohio. Since that first machine Akro-Plastics has grown and now operates 3 bi-axial rotational molding machines, 1 bi-axial shuttle machine and one rock ‘n oven molding machine. These machines allow Akro to mold product ranging in size from 4 ½” speaker boxes to well tanks or other items as large as 8’ (diagonal dimension) by 22’ in length. Our product lines range from polyethylene playground equipment, water sumps, parts for lawn maintenance equipment to containers molded with FDA approved polyethylene dispensers.

Using custom cooling fixtures and holding jigs we are proud to say that we hold some of the tightest tolerances in the industry. We have two 5 axis CNC routers for secondary cutting and trimming. We have assisted in the design of several products that are molded as a single unit, collage, and after machining and finishing produce as many as 7 different parts. Our finishing department takes great pride in producing very clean pieces and parts as well as fully assembled finished product. We have 800,000 square foot of floor space under roof and have the capability to direct ship or drop ship anywhere in the world.

If you are interested in our services please contact us. You can also view our brochure here.

Contact Us View BrochureBelow you will find reviews by some of our customers. If you would like to submit a review, please use the contact form located in the Contact Section.

"Akro-Plastics has provided quality products to my business for years. I will continue to do business with them and I would definately refer them to business collegues."

John Kline

Customer

John Kline

Customer

"We have never had a problem with Akro-Plastics services. They are prompt, courteous, and professional about business. Four stars!..."

Debra Thompson

Customer

Debra Thompson

Customer

"The people at Akro-Plastics are great! They are friendly and helpful. Our custom products are very well made and I would reccomend them to anyone."

Elizabeth Cray

Customer

Elizabeth Cray

Customer

Please use the form below to contact us. Once we recieve your form someone will be in touch with you as soon as possible. You may also contact directly via email or by telephone using the information provided below.

Akro-Plastics 900 West Main Street Kent, OH 44240

info@rotomold.net sales@rotomold.net

Main: (330) 673-6900

Toll-Free: 1-888-ROTOMOLD

Fax: (330) 673-3830